Necesidad Planteada

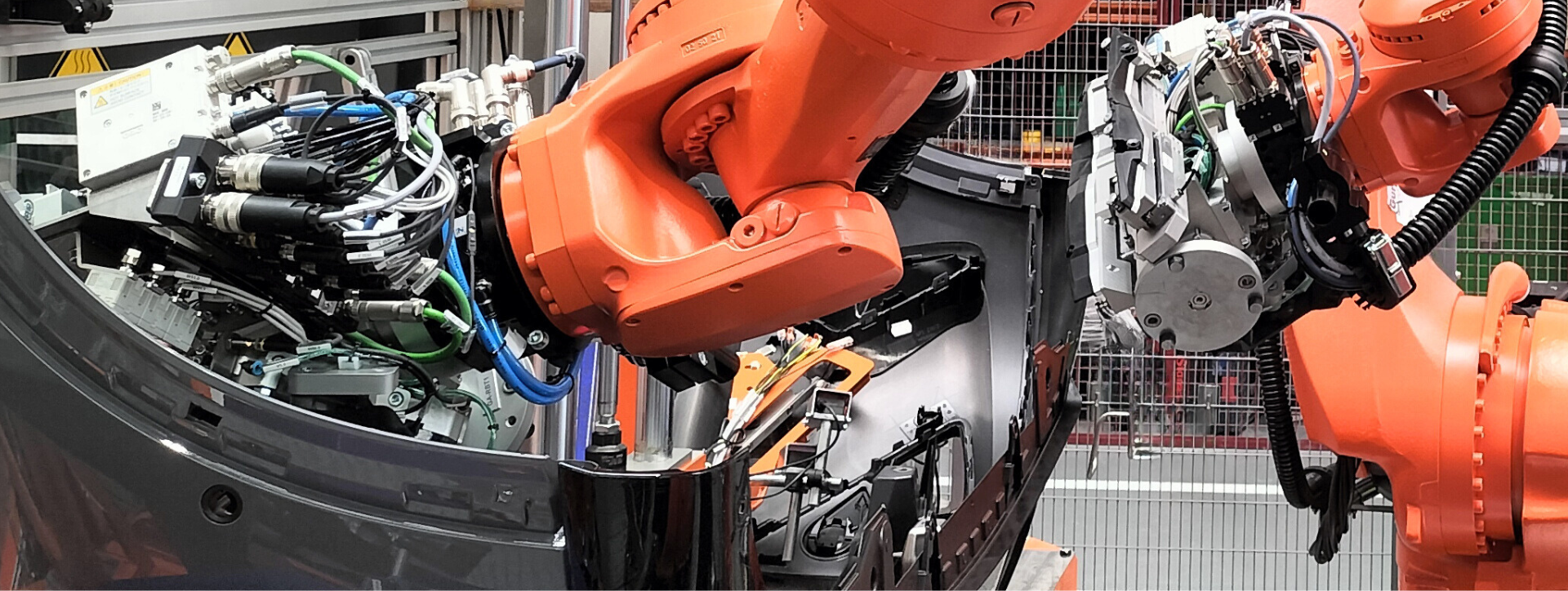

Installation developed for the automation of the continuity between the warehouse and cutting machines.

Solución

All the pieces that are going to result from the cut are labeled.

LABELLED

All the labels of the future pieces resulting from its cutting are placed on the original plate.

TRANSPORTS WITH MOBILE STOPS

The plates are inserted into machine 1 or 2, always in a good lateral position.

AUTOMATIC IDENTIFICATION OF THE PLATE REFERENCE

Reading of label placed in automatic warehouse.

Ventajas

Security, 100% since the machine is fully protected.

Productivity improvement, 100% of the cases are analyzed thus avoiding future quality rejections.

Fully automated production system.

Traceability in production guaranteed.