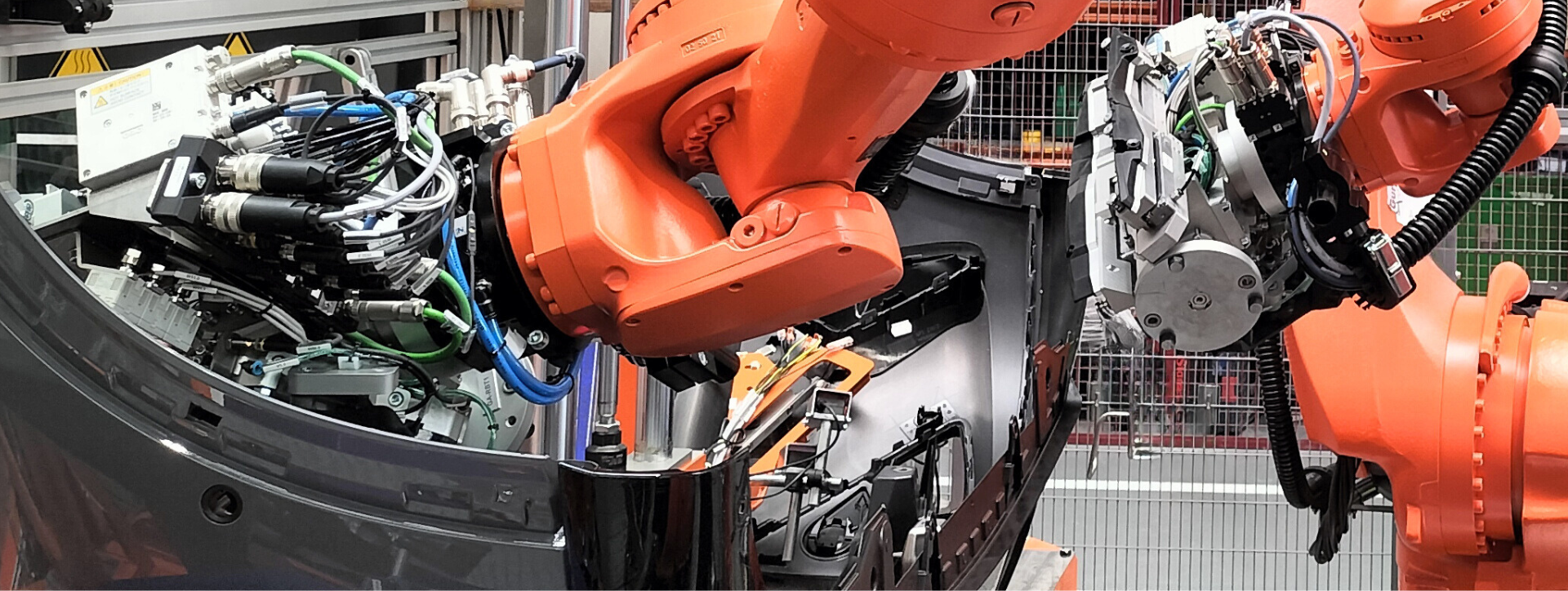

Installation developed for the engraving of automatic chassis for models 316, 370 and 380 at the SEAT Martorell factory.

UNIFIED TRIVALENT SCRATCH HEAD FOR MODELS 316, 370 AND 380

The engraving of the frame of the 3 models has been unified in a single head, providing the head with positioners that are automatically placed in the configuration that enters the installation.

In this way, it is possible to do, without 3 different heads, with the additional cost they involve, and the additional problems they could cause.

In addition.. the robot raises and lowers the bonnet car.

FRAME SCORING ENGRAVING UNIT

XYZ scratch engraving system, motorized tool with motors and spindles in the XY,

- Recording control software.

- Special system of fixing flange and engraved support.

- Pneumatically retractable centering system allowing the three vehicle models to coexist.