DIFFERENTIALS TEST

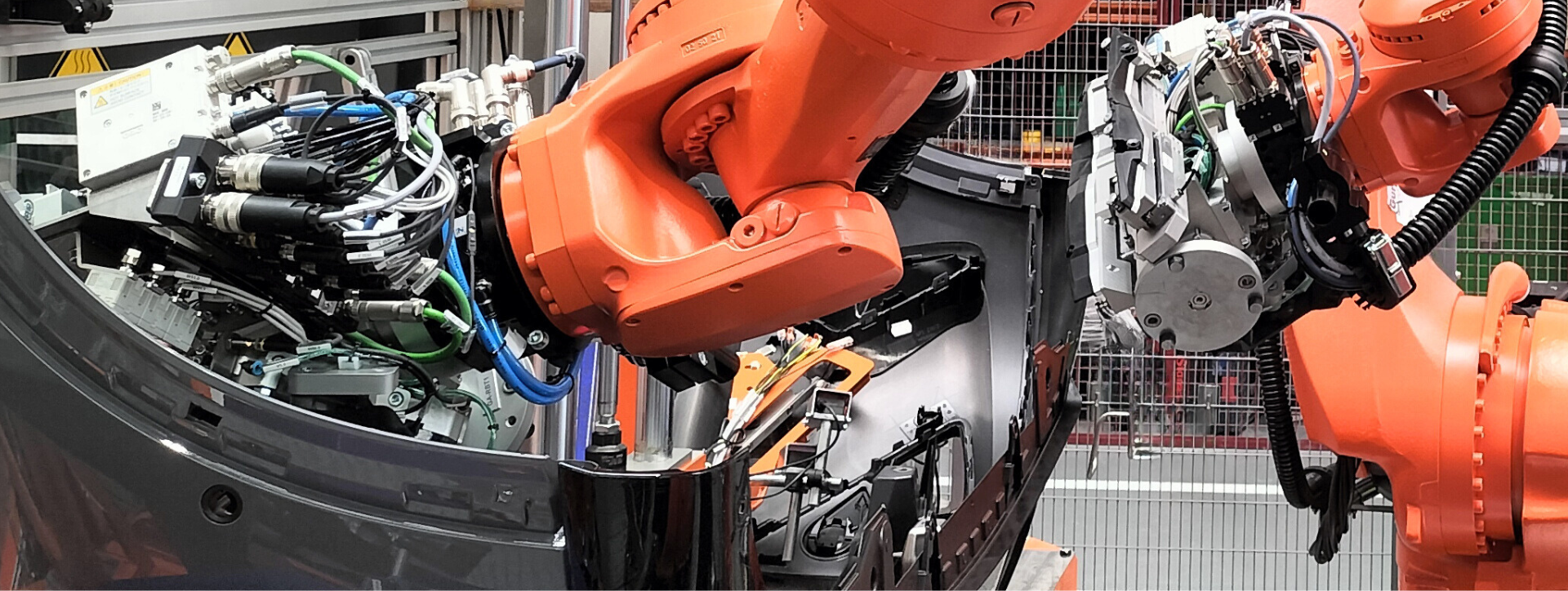

Installation developed for the automation of the total verification of all the elements that make up the differentials and their correct operation.

Installation developed for the automation of the total verification of all the elements that make up the differentials and their correct operation.

Full quality check. The system is capable of verifying all the components of various models, automatically adapting to each of them.

HANDLING AXIS

The system combines a transversal electric axis with a pneumatic vertical axis equipped with a turning unit and clamp.

This allows you to move items from one tape to the other and rotate them so they can be recorded in any position.

CONVEYOR BELTS

The installation consists of an arrival and departure tape, a parallel tape where the operations are carried out and a third where the badly recorded pieces are deposited.

INSPECTION STATIONS

The elements are passed step by step through the different posts where it is checked, using cameras, sensors, screwdrivers, that it is in perfect condition and corresponds to the expected model.