ENGRAVING STATION

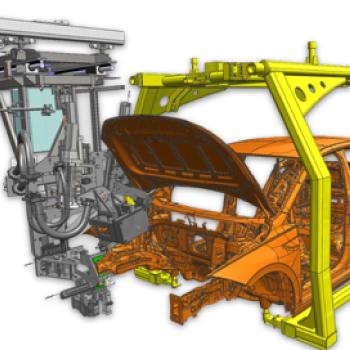

Installation developed for automating the engraving of the VIN code on the vehicle frame.

The system adapts to the different models that are currently in production, changing its position automatically according to the vehicle that arrives at the post.

Installation developed for automating the engraving of the VIN code on the vehicle frame.

The system adapts to the different models that are currently in production, changing its position automatically according to the vehicle that arrives at the post.

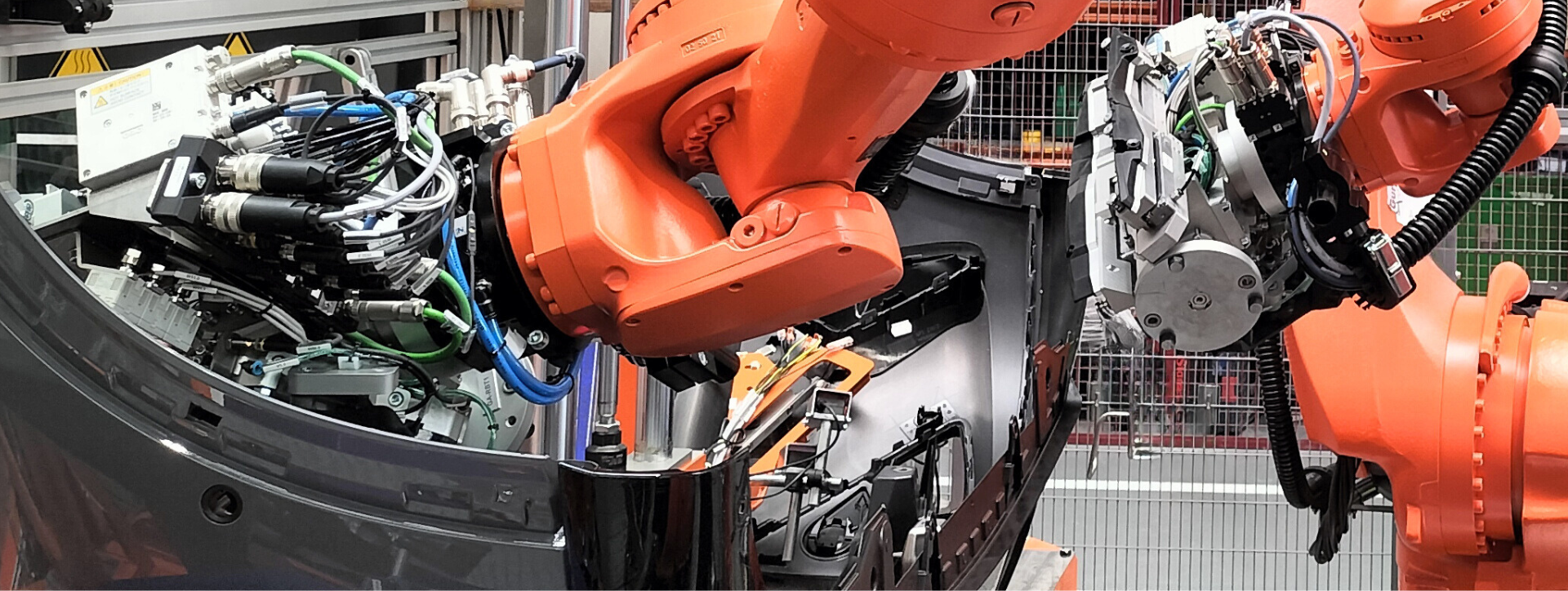

AUTOMATIC SYSTEM THAT ATTACHES TO THE VEHICLE and performs the work with the movement of the assembly work chain. The system is mounted on an XY Cartesian that intercepts vehicle traffic, is pneumatically coupled to the frame, and then moves with the assembly line. The system after recording the VIN code with a grating unit is removed and returns to an initial position to be attached to the next vehicle in the production line.

VIN ENGRAVING UNIT

XYZ grating engraving system, motorized tool with motors and spindles in the XY, pneumatic Z system.

- Recorded control software.

- Engraved fixing and support flange system.

COUPLING SYSTEM

Pneumatic system that is attached to the vehicle's side member, fixing the RPS.

- Plungers in Durogliss prior centering..

- Flange with RPS pneumatic positioner.

- Security sensor with distance control.