LAYOUT CHANGE

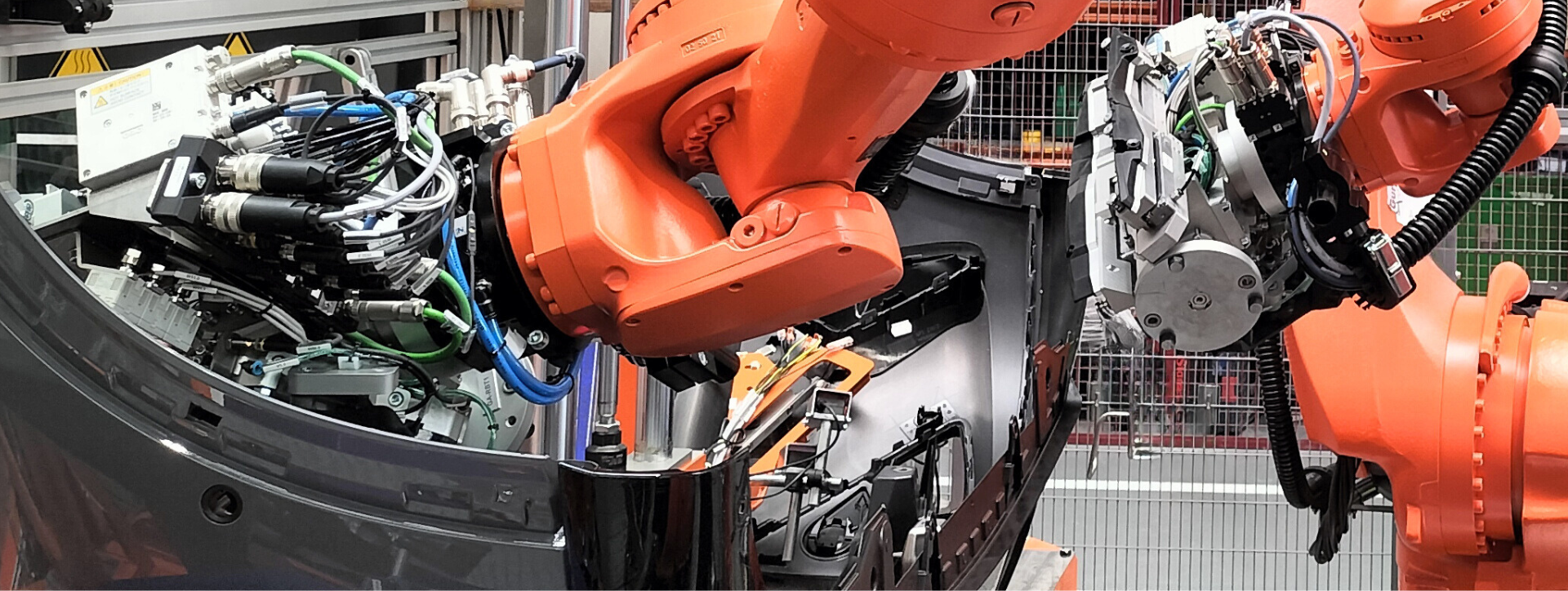

Project that proposes the modification of the plant layout to optimize the production process and the incorporation of new manufacturing lines.

Project that proposes the modification of the plant layout to optimize the production process and the incorporation of new manufacturing lines.

Coordination and execution of the transfer and movement of different machines and installations inside the client's plant. The project is undertaken in its entirety, covering all the phases of the process with actions of electrical disconnection, transfer, placement and fixing, electrical connection, requiring a crane due to the large size of some of the machines (presses, expanders, forking machines).

"Gurpea has a great team, both in planning and management and execution of the work, has all the necessary means for the assembly and transport of machinery, has very hardworking people who at all times adapted to the needs of the company, I am happy with the results and will certainly count on them for future work."

- Victor Fernández, Responsable Mantenimiento Industrial Kobol .