MACHINE VISION FOR DOOR VISION

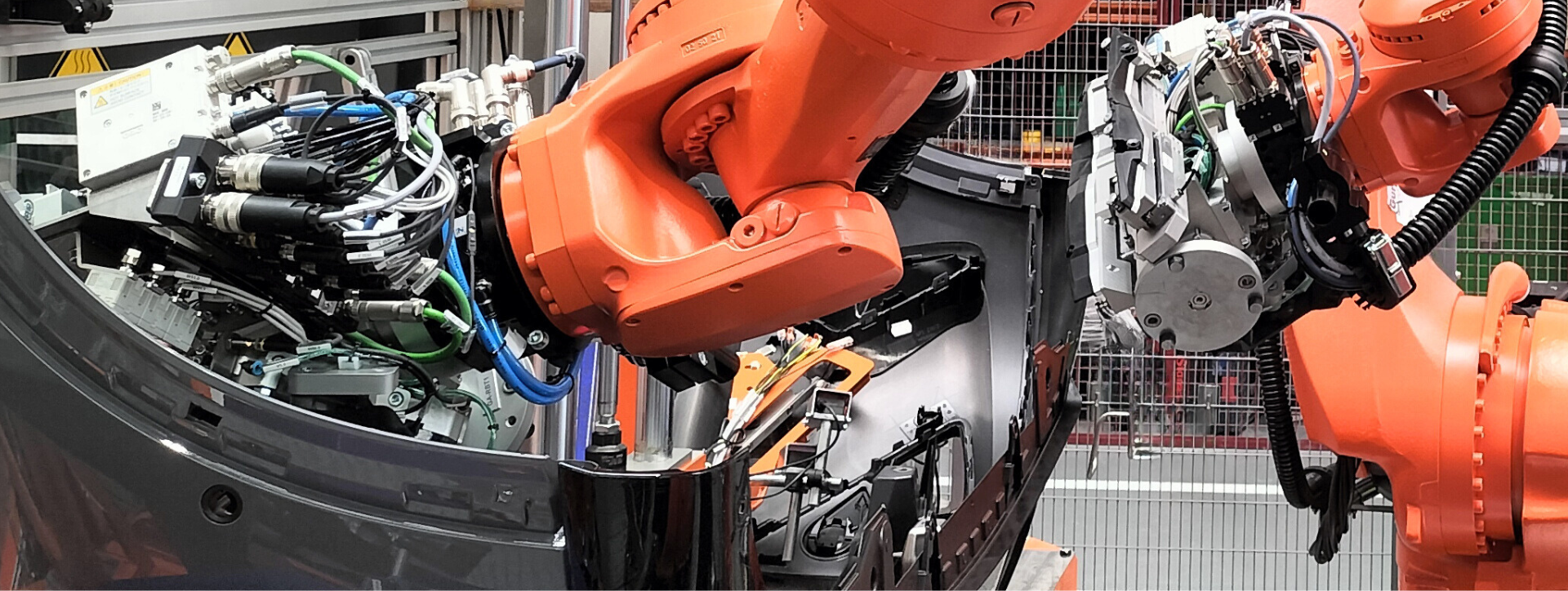

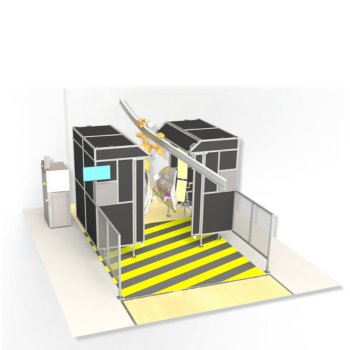

Automatic door verification station using machine vision cameras. The doors are moved by an overhead conveyor along the chain. When they arrive at the verification station, the machine vision cameras photograph and check that all the components have been correctly assembled.

This project was developed in collaboration with NEO DIGITAL SOLUTIONS.

Automatic door verification station using machine vision cameras. The doors are moved by an overhead conveyor along the chain. When they arrive at the verification station, the machine vision cameras photograph and check that all the components have been correctly assembled.

This project was developed in collaboration with NEO DIGITAL SOLUTIONS.

- Machine vision cameras (x18)

Machine vision technology allows automatic door checking without compromising line speed, in a confined space.

The verification system has 18 machine vision cameras, 9 for each door.

- (x22) Lightning elements

The system has 22 lighting elements to create the optimum environment for the machine vision cameras.

- Opaque enclosure

The verification station has an opaque enclosure to trap the light from the luminaires. This provides a better environment for the machine vision cameras.

- Flexible booth

The machine vision technology, combined with adjustments to the cameras, allows this post to be prepared to accommodate new door models in the future.

PARTNERSHIP: NEO Digital Machine Vision Technology

- Machine vision

As part of AI, machine vision allows machines to "see" and "understand" the visual world, automating tasks and improving product quality.

- Deep Learning Technology

This is a technology that allows a computer to learn like a human being, enabling machine vision systems to employ learning methods that are more robust, effective and very similar to those of the human brain.