Semi-automatic posts developed for the insertion of chrome and black trims on front and rear door weatherstrips.

CRADLES FOR WEATHERSTRIPPING REFERENCING

The station has machined cradles that copy the 3D geometry of the weatherstripping and are used for referencing them. They are also equipped with presence detection and OK positioning of the parts.

WEATHERSTRIPPING OPENING SYSTEM

An automatic system is available for opening the weatherstrip lip, which facilitates the pre-positioning of the trim by the operator@. All automatic systems are activated by means of a two-hand pushbutton that guarantees operator safety.

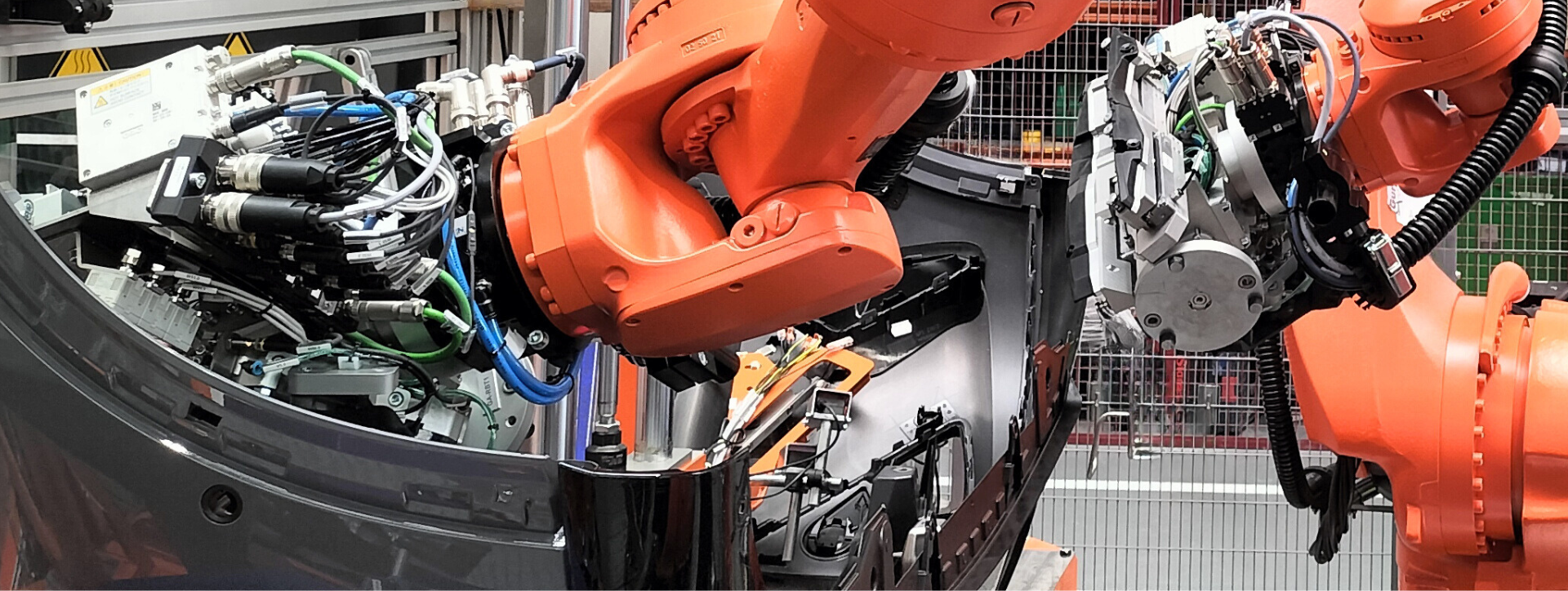

SYSTEM FOR PRESSING AND INSERTION OF TRIMS

By means of a mechanical system with a double floating wheel on 2 axes and a curved guide, the correct insertion of the trim into the door weatherstrip is guaranteed. A color sensor ensures the correct positioning of the trim type. As a visual aid to the operator, there are also mirrors mounted on the carriage itself.

PROCESS VISUALIZATION

The assembly stations have HMI touch screens where the operator is guided through the operations to be performed, the piece counter is displayed, cycle time used in each cycle, the correct status of all machine detections and the OK completion of each piece. Each workstation has LH and RH locations to work, automatically activating each side of the machine by turning the HMI.