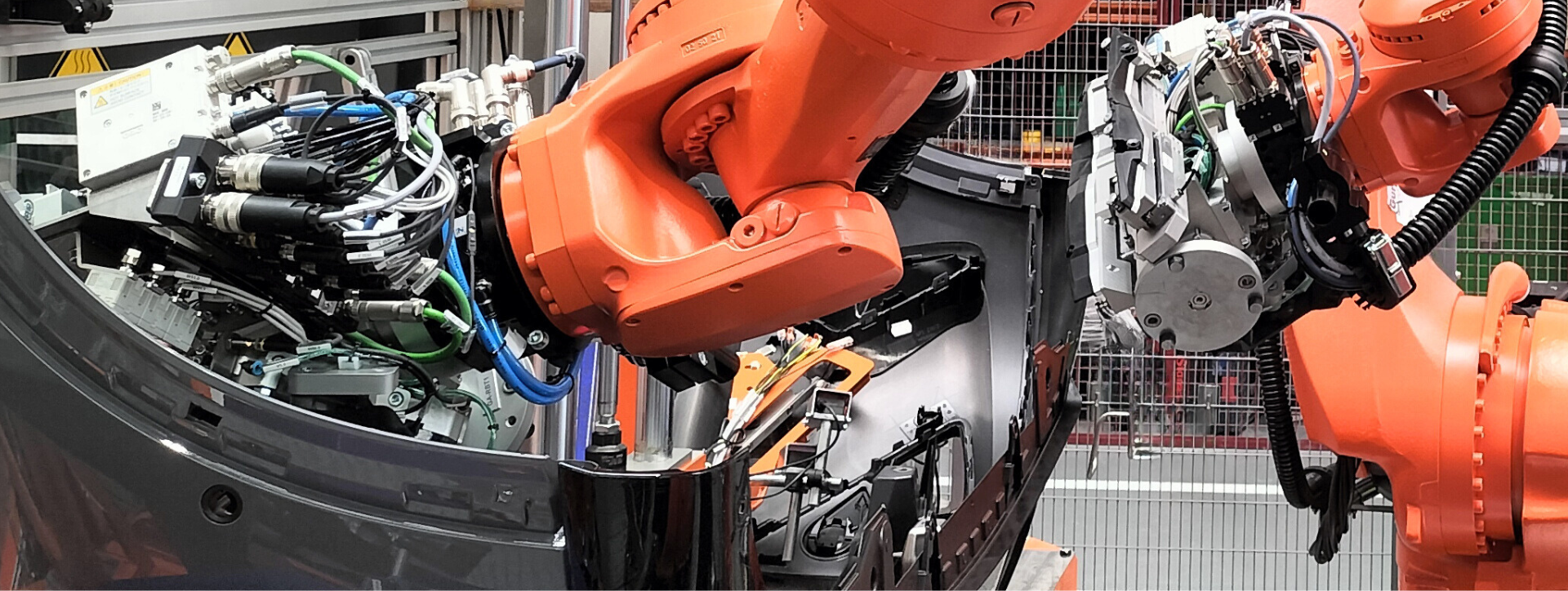

SYNCHRONISM: SCREWED PEDALS, DOOR SEALING AND FRAME VERIFICATION WITH ARTIFICIAL VISION

Screwing of the pedal boards,door sealing and verification of the frame number with artificial vision. The process is carried out in motion thanks to the synchronization of the 7th axis with the production line.

Installation developed for automating the screwing of pedal boards, vision of the frame code, and door sealing installation.

All operations are carried out automatically on the moving production line.

Synchronization of the position of the robot with the movement of the body. The system is composed of 3 tracks. The central track is coupled to the vehicle structure and is synchronized with the movement of the transport chain, transmitting the position and speed to the lateral tracks that support the 7-axis robots.

FOLLOWER CAR, SYNCHRONISM

Central track with coupling carriage to the vehicle structure.

PEDALS SCREWING

Robotic system for pedal screwing.

WEATHER STRIPPING

Robotized pneumatic tool that fixes the weatherstripping around the perimeter of the doors.

VIN VISION SYSTEM

Vision system composed of:

- Motorized cleaning system.

- Camera vision and lighting.