TRIVALENT AUTOMATIC ENGRAVING FRAME RETROFIT

Sector

Automotive

Cliente

SEAT

System developed to unify the automatic engraving frame for A1, IBIZA and ARONA models.

Necesidad Planteada

System developed to unify the automatic engraving frame for A1, IBIZA and ARONA models.

Solución

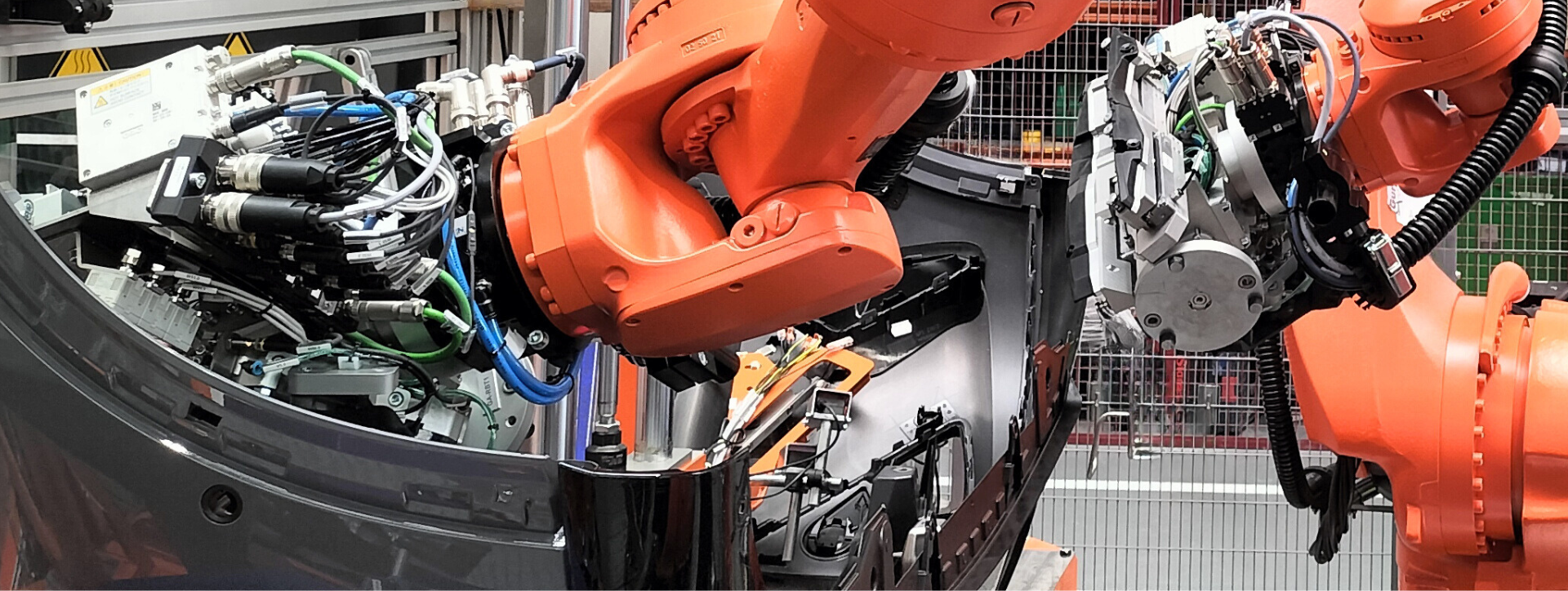

UNIFIED SCORING HEAD FOR 3 MODELS

Unification, in a single head, of the engraving of the frame of the 3 models, providing the head with positioners that are automatically positioned in the configuration that enters the installation.

In this way it is possible to dispense with 3 different heads with the additional cost and additional problems that this entails.

- The robot raises and lowers the hood.

- Each cycle is checked to ensure that the engraving tip is in optimum condition.

- A gauge is available for periodic quality testing.

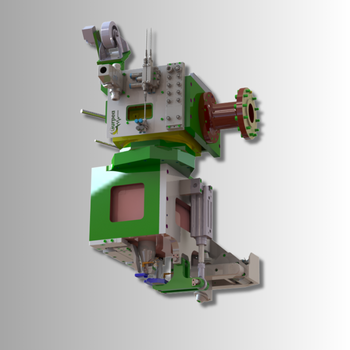

ENGRAVING TIP CHECKING STATION

HOOD CLAMPING 3 POSITIONS

FRAME SCRATCH ENGRAVING UNIT

- Engraving control software.

- Automatic positioning system for different geometries.

- Post engraving chip evacuation.

- Correct positioning detection.

Ventajas

Guaranteed security. The station is totally enclosed by a perimeter fence + scanner.

Reduction of non-conformities, thanks to the new head design that allows precise centering on the vehicle, always repeating the engraving position exactly.

Productivity improvement, since the whole process is carried out in the same station in a fully automatic way, avoiding head changes depending on the vehicle model.