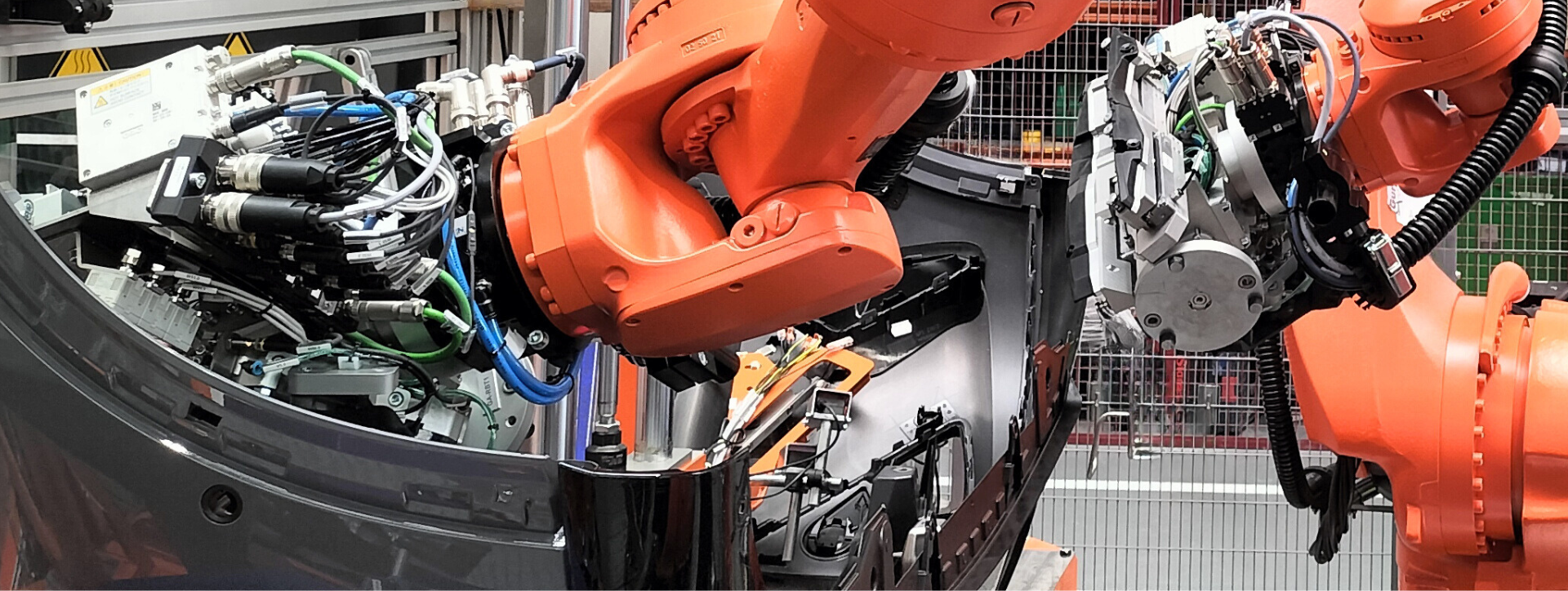

Modification of robotic installation of ultrasonic welding for fixing soundproofing fabrics in wheel arches. The modification adds two new turning systems in order to increase capacity and integrate the new models.

ULTRASONIC WELDING: The claw, equipped with a sonotrode and two tips, is mounted on a tilting system that allows two points to be made simultaneously on the surface.

This system simplifies the adjustment in the robot's programming, improving the quality of the points while reducing cycle times.

TURNING TABLE

Modular structure that is integrated into the machine to be able to integrate the new wheel arch models.

It incorporates:

- UGI (180º Intermittent Turn Unit)

- Harting connection system.

- System of centering in current structure.

- Transport system with forklift or overhead crane.

WELDING TOOL

Tool CAM mechanized in resin and with the geometry of the wheel arch of each reference.

ULTRASOUND CLAW

The claw incorporates a sonotrode system with two tips and also:

- Tilt system.

- Guided cylinder with controlled pressure.

- Sonotrode tips cooling system.