Installation developed for automating the supply of wheels to the assembly installation. The containers with six rollers with four wheels are deposited on a discharge system that feeds the entire line.

Wheel supply system with model traceability and security strategies. The entire accumulation system is designed as a lung that accumulates wheels for the benefit of logistics and possible incidents.

CONTAINER UNLOADING SYSTEM

Robust structure on which the container is deposited with rollers with wheels (6x4).

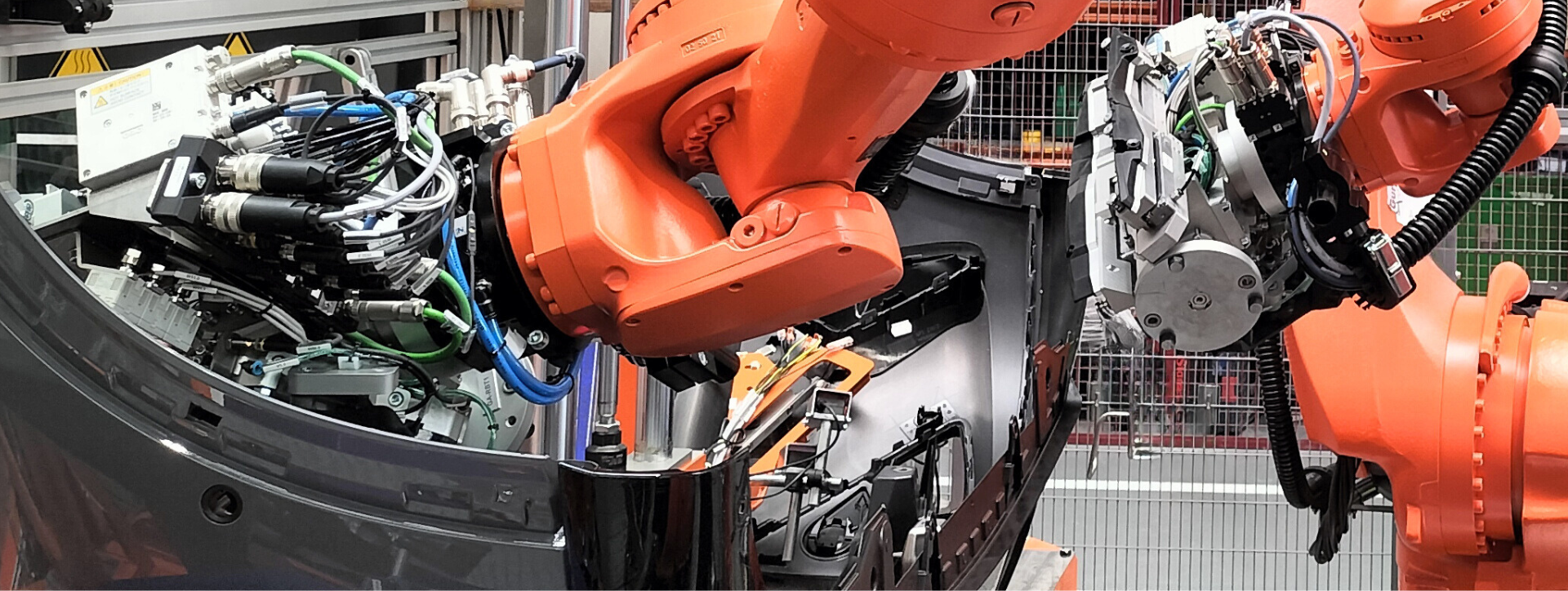

WHEEL DESTACKER STATION

System that unstacks the 4-wheel rollers to feed the line.

VISION CONTROL STATION

Control and vision station that identifies the tire model and distributes the wheels on each side of the line.

MODULAR ROLLER SYSTEM

Modular transport system of 800x800mm.